Projects

Dragflow Dredging for Construction field

From a long drawn-out process to working far more efficiently!

Our client, a sand and gravel producer serving construction and manufacturing relied on a traditional underwater excavation method: stripping land, casting a bucket, dragging material, piling, drying, then loading and hauling with multiple trucks. Rising costs, distance from the plant, and dragline depth limits made this process inefficient.

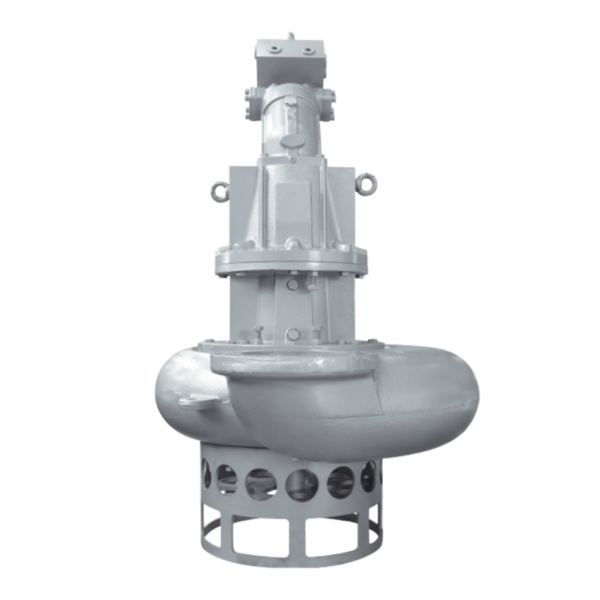

Technosub analyzed requirements and operational challenges to design a customized solution. The answer: Dragflow dredging technology (DRH85-160). Equipment was assembled on-site with assistance from two Dragflow technicians. This approach enabled deeper excavation near the plant, eliminating costly haulage.

Results: Productivity increased to 1,000 metric tons/day, then stabilized at 1,300 tons/day, extending the life of the operation without expanding its footprint. Technosub supported the client from kickoff to wrap-up, ensuring long-term performance through after-sales service. The client achieved rapid profitability.

At Technosub, success means tailored solutions and sustained support.

Highlights

Challenges to overcome